Ralf Sammeck, group executive board member, explained the shift to becoming an even more customer-oriented company.

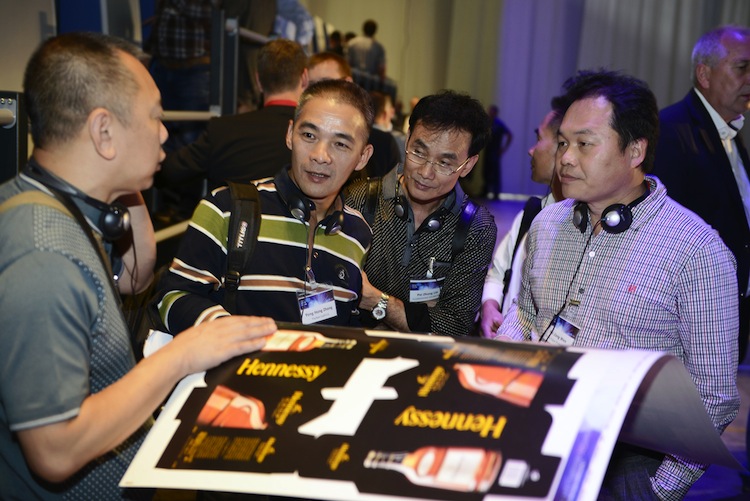

RADEBEUL, Germany—June 30, 2015—A large international customer event took place once again at KBA-Sheetfed Solutions in Radebeul, Germany, near Dresden, with the LED-UV and Traditional UV Conference from June 24-26. The event was a resounding success with around 1,000 print experts from more than 30 countries in attendance. This high level of interest shows just how important the topic of UV printing in diverse variations has now become to the print industry and how important sharing knowledge is. KBA is once again a trendsetter and trailblazer in the relatively young field of HR- and LED-UV in particular.

Nevertheless, the event did not just focus on this technical topic. The visiting print pundits were treated to two new product developments at once with practical live demonstrations of the Rapida 105 PRO unveiled at Print China in April and the inline Rapida RDC (Rotary Die Cutter).

When welcoming the guests, Ralf Sammeck, KBA group executive board member responsible for the new business unit KBA-Sheetfed Solutions, referred to the company’s all-encompassing approach in sheetfed offset. This includes technical and process innovations, intensive customer consulting, competent and fast-reacting after-sales service on all continents, user-specific solutions as a longstanding pillar of strength of the Saxon press manufacturer and setting benchmarks with Rapidas installed at other top performing printshops. At the end of the day it is all about helping our customers to be successful in the market. The KBA group has an exceptionally broad product portfolio and is a financially solid partner of printing companies.

Experts from the supply industry light up HR- and LED-UV from all sides

KBA key account manager Jürgen Veil also mentioned the company’s all-encompassing approach while presenting the podium discussion on cutting-edge finishing and curing technology. Technology partners from the world of printing inks (Flint, Epple, Inx), coating (Actega, Weilburger) and drying (AMS) answered a raft of user questions. When it came to ink and coating attention focused on the availability of special series, opaque white, metallic or Iriodin, as well as their suitability for food and non-food packaging, the toy and the tobacco industries. Questions were also asked about the print services available, suitable cleaning agents and technological features. The discussion on dryers also focused on practical topics: how do you know when a diode is broken, who can replace these, how is maintenance work carried out on LED dryers, how can the curing of LED inks be measured with measuring technology and much more.

The new Rapida 105 PRO was presented by Jürgen Veil with an impressive show in the middle of the assembly hall.

New Rapida 105 PRO with new TouchTronic operation

The new KBA Rapida 105 PRO medium-format press was presented in theory and practice as a raised six-color press with twin coaters for conventional inks, primers and UV coating. The new press scores points with its high level of variety in terms of kit (also perfecting) and fulfils the essential requirements of commercial and packaging printers. It will soon be on display in the KBA demo centre in Radebeul featuring a ColdFoiler for high-quality cold-foil finishing. With speeds of up to 17,000 sheets/hr. and a high level of pre-set capabilities, the press offers somewhat more comfort and performance compared to the Rapida 105 which is still available (see press release 15-023 from 13.04.2015). In terms of price and performance, the Rapida 105 PRO is positioned between the Rapida 105 and Rapida 106, which is the world’s number one press in its format class with speeds of up to 20,000 sheets/hr. and the shortest makeready times.

The visitors were treated to a demonstration of a job change with a fast coating plate change and coating change as well as a substrate changeover from 250 g/m2 (160lbs) to 1.1mm-thick. The new intuitive TouchTronic operating system with a 16:9 touchscreen was a further highlight. All relevant information can be accessed on the touchscreen with a maximum of two touches. New features include comfortable job changing at just one press of a button (One Button Job Change) and the clearly arranged list of jobs. TouchTronic is expected to be gradually built into all new Rapidas in all format classes by the beginning of 2016.

Demonstration of the strengths of LED-UV in all format classes

A series of press demos was dedicated to UV and finishing: cold-foil kit in connection with HR-UV technology on non-absorbent substrates was shown on a six-color Rapida 106 with coater and ColdFoil Micro. When changing jobs the visitors saw a switch from self-adhesive labels to PP film. This was in addition to a demonstration of an automatic anilox roller change with AniloxLoader and automatic coating plate change with DriveTronic SFC. Various print jobs were shown for work and turn on a new five-color Rapida 75 with coater and LED dryer. One of the highlights of the demonstrations was the brilliant print quality on offset paper delivered by LED-UV.

Dirk Winkler talked the visitors through a print demo on an eight-color Rapida 106 perfector with coater and LED-UV for both sides of the sheet.

KBA presented a job printed with in-mould film and low-migration LED-UV inks on a Rapida 145 (six colors with coater). This was followed by jobs demonstrating fast work and turn with three different types of paper (matt, gloss and offset). The focus of the job changes was placed on automation modules for fast setup. These include DriveTronic SRW (simultaneous roller washing) and DriveTronic SFC coater with AniSleeve sleeve changing.

Rapida 106 remains makeready world champion even with LED-UV

The afternoon program began with a keynote talk from David Bland of Blackmore Ltd. in Longmead, Great Britain. He is one of a raft of users who have already implemented LED-UV technology and he reported on his experience with this new technology.

Afterwards, an eight-color Rapida 106 with coater and perfecting for 4/4 production, showed what it could do. It was impressive to see that the sheets were dry immediately after passing through the LED dryer. Despite the sheets’ high-color imposition, the print quality on offset paper in LED-UV was outstanding and the production of 10 different jobs took place within a short time. This included posters with Flying JobChange. The KBA Rapida 106 defends its title as makeready world champion even with LED technology. The press’ technological highlights include the cleaning and supplying of the coater with UV coating during production.

Launch of the KBA Rapida RDC

The Rapida RDC was also unveiled at the open house. It features a rotary diecutter based on Rapida components that can run at speeds of up to 14,000 sheets/hr. It is equipped with various automation modules for reducing start-up times (e.g. automatic cutting die change). Its intuitive operating concept is based on that of other Rapida presses. Job profiles can be stored shortening makeready when processing repeat jobs. Furthermore, it can be flexibly integrated into MIS systems offering the user complete transparency within their company. Existing systems, such as KBA LogoTronic, can also be applied.

Grooving and embossing took place in the Rapida RDC’s first unit and diecutting took place in the second. After a quick cutting die change in the second unit, the visitors were treated to diecutting of self-adhesive labels.

KBA invited the visiting print experts to a popular beach bar situated directly at the river Elbe in the evening. The guests had the opportunity to converse informally with each other, to network or simply enjoy the view of the historical old town of Dresden on a summer’s evening.

- Companies:

- KBA North America

Koenig & Bauer Announces Management Succession

Koenig & Bauer Announces Management Succession

Koenig & Bauer Wins Best Folding Carton Case Study

Koenig & Bauer Wins Best Folding Carton Case Study

Lewisburg Printing Foresees Gains with Rapida 145

Lewisburg Printing Foresees Gains with Rapida 145

RMGT 9 Series Perfector Helps Verdant Graphics Flourish

RMGT 9 Series Perfector Helps Verdant Graphics Flourish

JD Graphic Cuts Costs with RMGT Offset Perfector

JD Graphic Cuts Costs with RMGT Offset Perfector

Heidelberg Offers Print Shops Prospect of Continued Profitability

Heidelberg Offers Print Shops Prospect of Continued Profitability