At the beginning of the digital printing era, there were legitimate concerns about certain types of finishing equipment not being tailored to this type of work. Vendors replied in kind but, printers being printers, found new applications that complicated matters even further.

What we have now is a rich tapestry of possibilities when it comes to finishing digital output in an in-line, off-line or near-line fashion. We’ve rounded up a group of well-known printers—practically celebrities in their field—to offer the whats and whys behind their approach to binding and finishing.

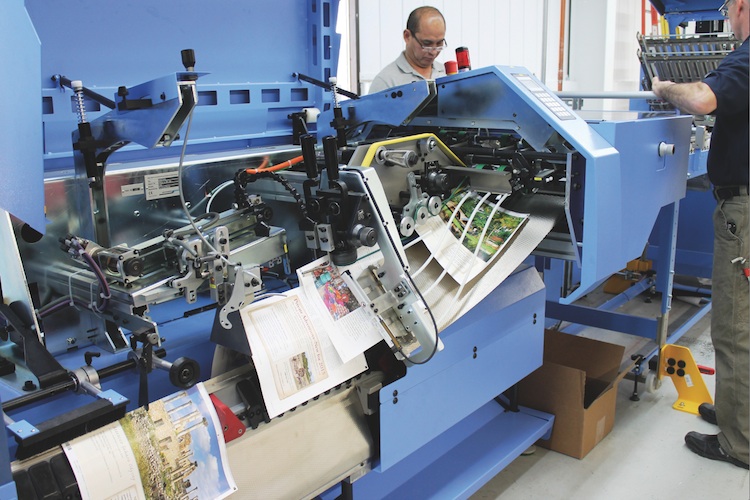

Leading off is Wilen Direct of Deerfield Beach, Fla., one of the nation’s leading providers of direct mail solutions and a member of the Wilen Group of Farmingdale, New York. Jeff Obermiller, vice president of manufacturing, notes that in-line finishing has always been the preference due to factors including turnaround time, labor, control of sequential sort, as well as being one-to-one with the printing process.

“Off-line is also a viable solution, as it opens up endless market solutions for innovative companies to offer their clients,” he says. “Off-line also offers excellent control of products in terms of accuracy when combined with state-of-the-art scanning equipment. Technology is such today that you are only limited by your imagination.”

Obermiller firmly believes that the evolution of continuous-feed digital printing has been delayed due to finishing equipment issues. Speed and quality were not the culprits as much as an actual lack of gear intended to address a given task.

“Coming from the commercial web side, we are used to robust equipment built to stand up to the rigors of 24/7 production,” he notes. “Business forms-type equipment just wasn’t a viable solution. Although the technology side of it is perfect for a variable solution, it’s prone to constant breakdowns, making it impossible to achieve consistent production, which ultimately impedes growth.

“We looked at many different types of finishing equipment, only to be disappointed again and again. We finally decided to build our own variable finishing equipment around a VITS variable cutter. It took some months, but the result is consistent, 24/7 production. As with any new process there are always obstacles. A company must be innovative and have a highly adaptable team. Wilen Direct is fortunate to have both.”

Obermiller points out that Wilen Direct is in the process of adding another VITS rotary cutter, backed by more custom-built finishing equipment. Wilen is extremely proprietary about certain aspects of its gear, but maintains that the VITS rotary cutter has proven to be a solid cornerstone around which the company has devised its finishing solution. Obermiller sees it as one of the factors contributing to the evolution of web offset to digital web printing.

The Case for Off-Line

Fellow direct mail specialist Data-Mail, of Newington, Connecticut, produces millions of highly customized direct mail pieces in full-color each month. The company offers cut-sheet variable digital printing via its six Xerox iGen presses and continuous-feed inkjet printing through a pair of Canon Océ JetStream 2200 presses and an Océ ColorStream 3900. Bruce Mandell, president of Data-Mail, notes that all non-cutsheet digital output is run roll-to-roll, and the jobs are then taken off-line to run on a wide range of finishing gear. All personalization equipment runs off-line.

“We have 24 toner-based lasers, and the basic thought process is that as a direct marketing job shop, although we have continuity programs that come in weekly and are consistent—weekly, monthly or quarterly—the actual specifications of those jobs change,” Mandell says. “Because of that, we don’t think it’s efficient to set up (in-line) bindery equipment, change folders, etc.

“That’s especially true for high-speed inkjet printing. They’re multimillion-dollar machines and we don’t want them sitting idle because we’re working on our folds, or are down because of jams. We want to run those full-out at the highest level of efficiency we can get, then take those rolls to the bindery.”

Data-Mail uses Miyakoshi unwind/rewind units on the JetStream 2200s and a Standard Hunkeler unit on the ColorStream 3900 to produce tight, solid rolls for delivery to its binding department, which features 11 lines. That redundancy allows the company to run the high-speed inkjet presses all day long, according to Mandell.

The inkjet machines have allowed Data-Mail to be a bit adventurous, including one scenario that sees it running rolls through the inkjet press to create envelope-type packages. Data-Mail inkjets the inside of the envelope—full-color and variable—as well as the outside, while creating a pocket.

“We’ll take it through an inkjet machine, sheet it, run it through an envelope converter and create the formation of an envelope,” Mandell explains. “But we don’t glue the sides. Then you can run it through an inserter, give it additional pieces and glue it. We’ve been doing it for about six months and it’s really been well-received.”

Each Method Serves a Purpose

In Lowell, Massachusetts, DS Graphics churns out $42 million in annual revenue by providing printing (60 percent of its business), mailing (30 percent) and fulfillment (10 percent), with a healthy mixture of digital cut-sheet and digital inkjet web printing at its disposal. According to Jeff Pallis, president of DS Graphics, the company does in-line, near-line and off-line finishing, as they all serve a purpose in its grand scheme.

“We use in-line finishing for cut-sheet and final trim products on an inkjet press,” Pallis says. “We also do punching and saddling in-line on our cut-sheet digital, inkjet near-line, roll-to-roll for mail inserting and cut-sheet. We have just introduced a new Muller Martini (Primera E140 saddle binder), the first in the world of this type, that can produce both cut-sheet variable digital and static at the same time. For off-line finishing, we do cut-sheet folding, inserting, saddle stitching and perfect binding.”

The Muller Martini has a plow folder on the end, which allows users to do cut-sheet folding and accumulating at high speeds for saddle stitching. That is phase one of the Muller installation. Phase two will allow DS to take inkjet printed rolls to the saddle stitcher.

DS Graphics has enjoyed much success with hybrid digital/offset jobs, and part of that success had to do with investing heavily in its inserting and finishing operation. For example, one job might be 100,000 copies of a 36-page, self-cover, saddle-stitched catalog. An offset shell accounts for 32 of the pages, with the cover containing the only variable content (logo, address, tagline). The cover is printed offset in order to match the crossover going to the text, and then it is run cut-sheet digital for the logos, addresses and other variable content.

Initially, DS Graphics produced the catalogs with cut-sheet digital but, as the counts climbed to 20,000 and 30,000, the jobs were taking 30 to 80 hours apiece. That, as Pallis observes, is not print-on-demand work. But, by moving the jobs from their Xerox iGens to an HP T200 series inkjet web press, the production time shriveled from 80 hours to 10 hours.

Predictably, that caused a bottleneck for the finishing department. By moving output to near-line, DS Graphics is able to finish at higher speeds, even with specialized finishes.

“One reason we lean near-line or off-line is that our work varies,” Pallis notes. “With inkjet, we’re doing book work, transactional work or direct mail. We can’t afford to have any downtime. If you don’t have backup machines, it throws a huge wrench into the works. You need redundancy throughout.”

Finishing digital output is certainly not without challenges. “When you’re getting into inkjet technology, the beauty is you can make everything variable and it’s very cost-effective,” Pallis notes. “It bridges the gap between offset and cut-sheet digital. We’ve found the tracking of the work through the entire finishing or mailing operation is getting complicated, so we have to get software, cameras and other solutions to manage workflow.”

DS Graphics plans to look at perfect binding equipment for book work, along with an in-line folder. The company invested roughly $4 million on inserters in its mailing area to be able to process variable work. Pallis says the firm is adding every possible option (e.g., cameras and taglines for inserters).

“The machines are becoming more complicated and expensive,” he concludes. “But we want reliability and verification of the quality.” PI

Battlefield Press Adds Allpro 110 Folder Gluer

Battlefield Press Adds Allpro 110 Folder Gluer

How Spot UV is Driving Growth for Print Businesses

How Spot UV is Driving Growth for Print Businesses

Gallus Announces Availability of Gallus MatteJet

Gallus Announces Availability of Gallus MatteJet

Graphco Unveils Auto Stud Welding at ISA Sign Expo 2025

Graphco Unveils Auto Stud Welding at ISA Sign Expo 2025

Wallace Graphics Installs MBO Finishing Systems

Wallace Graphics Installs MBO Finishing Systems

King Printing Expands Capacity with New Diamant MC 60 from Muller Martini

King Printing Expands Capacity with New Diamant MC 60 from Muller Martini