A few years ago at a PRINTING United Alliance’s Digital Packaging Summit, a panelist from Microsoft explained that the company vets every printer and converter it works with by looking for a statement of sustainability on the company’s website. What happens if there isn’t one? It doesn’t do business with that company.

While that might seem like an extreme example, Gary Jones, vice president of Environmental, Health, and Safety Affairs at PRINTING United Alliance, explains that with new regulations and legislation being passed on a regular basis, there has been a “transition from sustainability being a ‘nice thing to do’ to a ‘must thing to do.’” That’s why it’s important to have a sustainability plan in place and to be prepared to speak with your customers about it on a deeper level.

“Customers easily see through empty sustainability initiatives,” Jones says. “In addition, some of them are hiring sustainability professionals that will be asking the hard questions. To have a productive conversation with customers that have sustainability as a key initiative is to be prepared with a genuine and transparent message.”

He says this can be achieved by developing metrics that clearly illustrate a company’s environmental impact and the programs it has implemented to address environmental concerns. Some metrics include carbon emissions, solid waste generation and recycling, incorporation of recyclable substrates, and using sustainable ink systems, Jones notes.

“Being able to explain what the company has done and plans to do along with supporting metrics provides a powerful message to customers, employees, and the community,” he says.

Illustrate the Environmental Impact

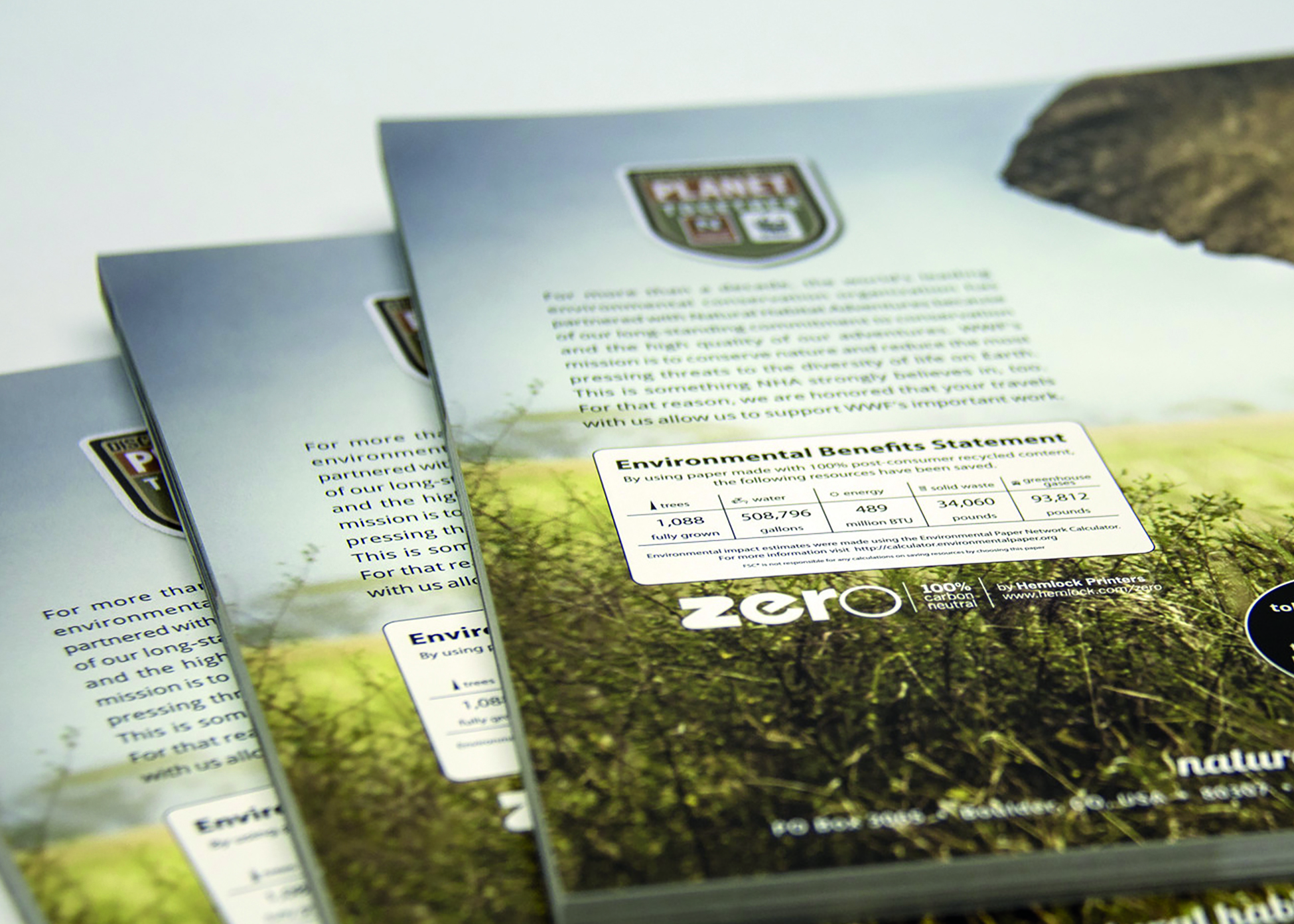

Providing specific metrics is something Hemlock Printers, based in Vancouver, British Columbia, has been doing “for the better part of 15 years,” explains Doug Climie, vice president of sales at Hemlock.

For example, the company is able to provide customers with an “environmental benefit statement” when they choose 100% post-consumer stocks, Patrick Brown, an account manager at Hemlock, explains.

“Our customers get very specific data for how much water that’s saved, how many fully grown trees you’ve saved from being cut down, electricity usage, all of those kind of helpful data points that the organization can then go share with their community or just keep internally for their own measuring and knowledge,” he says.

Hemlock can provide customers with a snapshot of its environmental impact for a single project, but it also offers what Climie describes as an “annual summary statement” for a client that is doing multiple projects over the year.

“This is especially important to clients who share that same sort of philosophy around sustainable production and distribution, and this statement is invaluable to them,” Climie says. “For them to be able to communicate to their internal and external stakeholders, it delivers a powerful message of their commitment to ethical and responsible practices [that] extends beyond their own production.”

The company, which was the first FSC-certified printer in Western Canada, launched a carbon neutral program in 2009 called ZERO. The program gives customers the opportunity to offset the GHG footprint of their print project through investments that support North American and global forest conservation efforts, Hemlock also shares the ZERO branding on materials if customers opt into the program, clearly illustrating their commitment to taking positive steps toward climate action.

“When we introduced the program 15 years ago, it was new, and unique to the market,” Climie says. “There are now additional options that have embraced the concept of offsetting the environmental footprint of print, including reforestation and other initiatives. But we are committed to continuing and expanding our program it as well. There are various levels of measuring the product lifecycle and we are continuing to make sure that we’re capturing every possible aspect – from source to production to usage and recycling.”

Communicating with Customers is Key

In 2023, Salt Lake City, Utah-based Hudson Printing became North America’s first Carbon Balanced printer, which is a certification in conjunction with Carbon Balanced Paper North America, the Sustainable Paper Group, and the World Land Trust. Nicole Larson, project manager at Hudson Printing, emphasizes the importance of understanding each customer’s unique sustainability goals.

“When collaborating with clients,” she says, “we make it a priority to ask about their sustainability objectives to ensure our solutions align with their values.”

“Taking the time to understand a client’s business fosters a deeper, more meaningful relationship than one might expect,” Larson continues. “Make it a part of your conversation to ask if they have sustainability goals for their company. If they don’t, then you get the opportunity to share your incredible sustainable solutions and let them know you’re here to support them whenever they’re ready to explore those options. It often sparks interest because sustainability is a growing priority for many businesses.”

Part of that communication should also be discussing the environmental impacts of printing. Jones says there are three areas that should be discussed.

First, Jones says to touch on the materials. He notes things such as “the source of the substrates, the recycled content of the substrate, the biorenewable content of the inks and coatings, and the air pollution emissions associated with the materials.”

Next, discuss the “fate of the finished product.” Meaning, “can the product be recycled and become part of the circular economy?” he asks.

Finally, it’s important to discuss the manufacturing process with the customer. Explain to them what the company is doing to reduce its impact on the environment, how it is addressing air pollution emissions, and hazardous and solid waste generation.

Educating customers in this matter can be something like what Hemlock provides in its environmental statements, but no matter what the delivery method, Jones notes printing operations need to have these metrics available.

“There is a tremendous amount of pressure on the supply chain for companies to not only understand their environmental footprint, but to then take steps to reduce it,” he says. “Print customers are starting to ask the questions of their print service providers and printing operations need to be prepared to answer them. Having a full understanding of their environmental impact allows a company to identify reduction opportunities, set targets, and track progress over time.”

It’s also beneficial to have an understanding of what sustainability goals are common for print buyers moving into 2025. Jones points out that one of the biggest focuses right now is greenhouse gas emissions.

“Some customers are requesting their PSP to provide detailed greenhouse gas emissions via the Carbon Disclosure Project,” he says. “The emissions include Scope 1, 2, and 3. The primary driver for this information are the commitments being made by some customers to reduce their emissions from their operations and supply chains.”

Another concern for print buyers right now is the assurance that their products do not contain any per- and polyfluoroalkyl substances, known as PFAS, Jones explains. He says that several states have banned the intentional addition of PFAS to products, including apparel and packaging.

Addressing Concerns About Cost

One of the common misconceptions about choosing sustainable printing practices is that it will cost more.

“Many people think [sustainable options] are going to be way out of budget,” Brown notes. “But there are many options we can explore to keep them within their budget.”

If a customer isn’t familiar with sustainability in the printing industry, its importance, or the realistic cost/benefit analysis of choosing a sustainable product, Hemlock will have a conversation with them first.

“Starting with communicating Hemlock’s mindset around sustainability and how we’ve developed things internally to align with that, and then clearly explaining how we can translate that to the shared benefits of environmental printing for our clients, and making projects carbon neutral FSC-certified using 100% post-consumer papers,” Brown says. “Our website has a great overview of the program and the specific projects our offset portfolio supports (such as the Great Bear Forest Carbon Project on the west coast of Canada and the Darkwoods Forest Carbon Project in the Selkirk Mountains) – so I’ll often share my screen with clients to walk through the very substantial, real-world benefits of safeguarding intact forest biomes that [their] investment supports.”

Even though cost is a concern for many print buyers, for some, price may not be the only driving factor, Jones says. He notes that with new regulations and legislation being introduced, such as the emergence of the Extended Producer Responsibility (EPR) laws for packaging and printed paper, print buyers want to avoid being prohibited from placing their products into the market due to a ban.

“EPR programs are designed to increase the recycling rate of covered products by passing along the cost of recycling to those who are selling or distributing the product in the state,” he says. “Fees will be charged for all covered products with higher fees assessed on products that are more difficult to recycle. In addition, some programs also mandate that certain products contain a minimum amount of recycled content. Customers need to be made aware of the potential significant price increase associated with putting their product into the marketplace.”

Jones also notes that there is a growing move toward sustainability for consumers, meaning price can no longer be a determining factor in printing purchase decisions.

“Many recent consumer polls have shown a clear majority of people expecting companies to produce more sustainable products,” he says.

Committing to Sustainability

For some companies, Larson notes, committing to sustainability might stem from customer demand, but she says print service providers “should take a proactive approach by fully understanding what sustainability means for their business and how it can drive value.”

“Strive to be a trailblazer in your industry,” she says. “At Hudson Printing, we’ve taken bold steps, invested time and resources, and developed innovative solutions to offer meaningful value to our customers. The rewards have been tremendous, not just in business success but in the pride that comes from making a real difference. Whatever your path, aim to lead, to innovate, and to inspire. Ask yourself, ‘What will set us apart and position us as a leader in our field?’ By embracing that mindset, you can create lasting impact and elevate your business.”

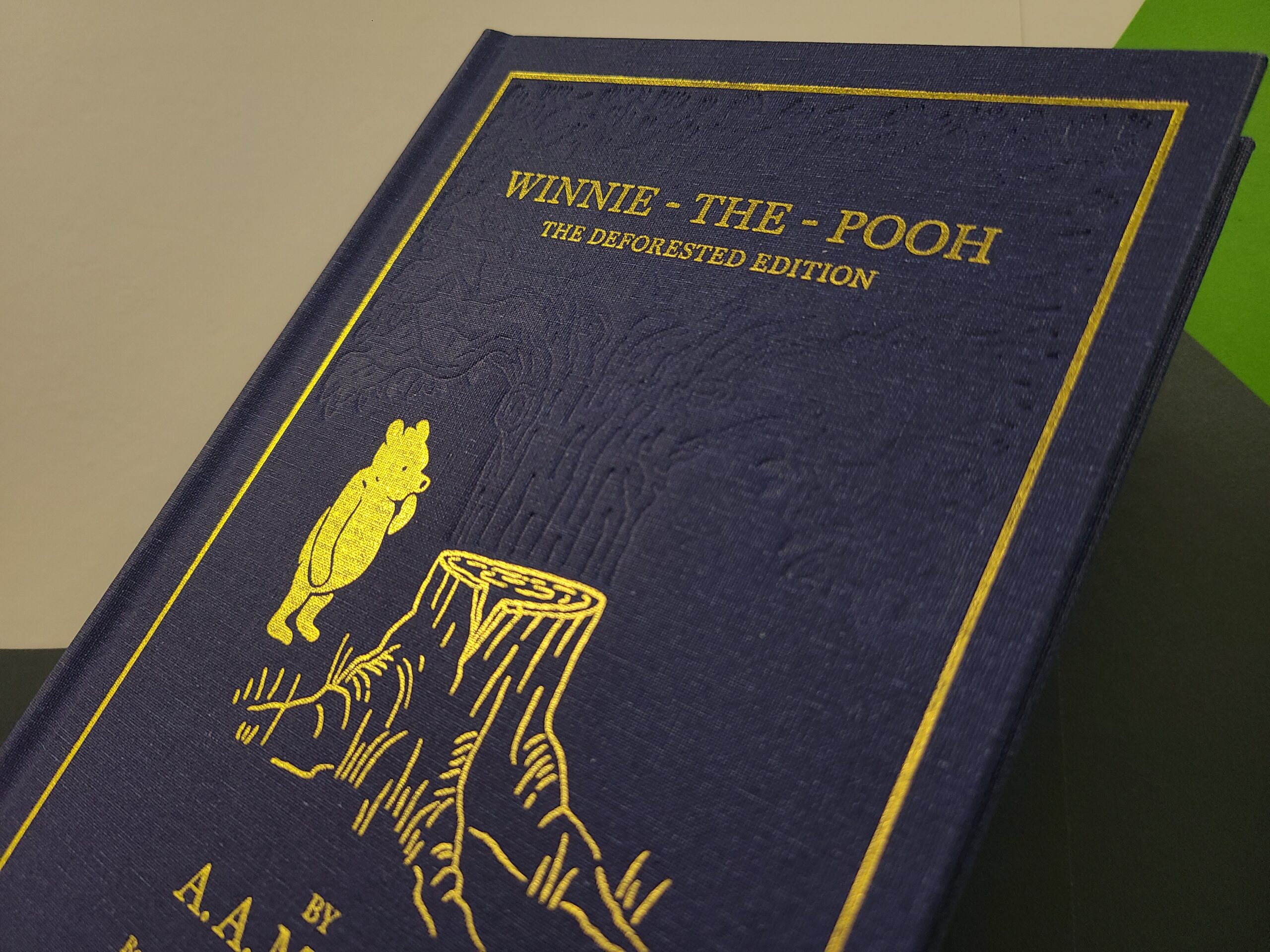

Winnie the Pooh Tackles Deforestation

This book, “Winnie the Pooh – The Deforested Edition,” which was produced by Vancouver, British Columbia’s Hemlock Printers, was the 2024 Canadian Printing Awards winner for Most Environmentally Progressive Printing Project. This project is special in that it was completed for Hemlock’s customer “Who Gives a Crap,” a producer of toilet paper that is dedicated to sustainable practices.“The client for this project, Who Gives a Crap, is passionate about preventing deforestation through their work in the toilet paper industry,” Doug Climie, vice president of sales at Hemlock, explains. “To combat the deforestation that is already prevalent in the market, they manufacture bamboo and recycled fibre toilet paper.”

The Winnie the Pooh book had to be a reflection of the company’s mission, meaning that it was “essential that no deforestation occurred for its production,” Climie says.

“We achieved this through careful selection of substrate materials,” he explains. “The book utilizes only recycled paper content.”

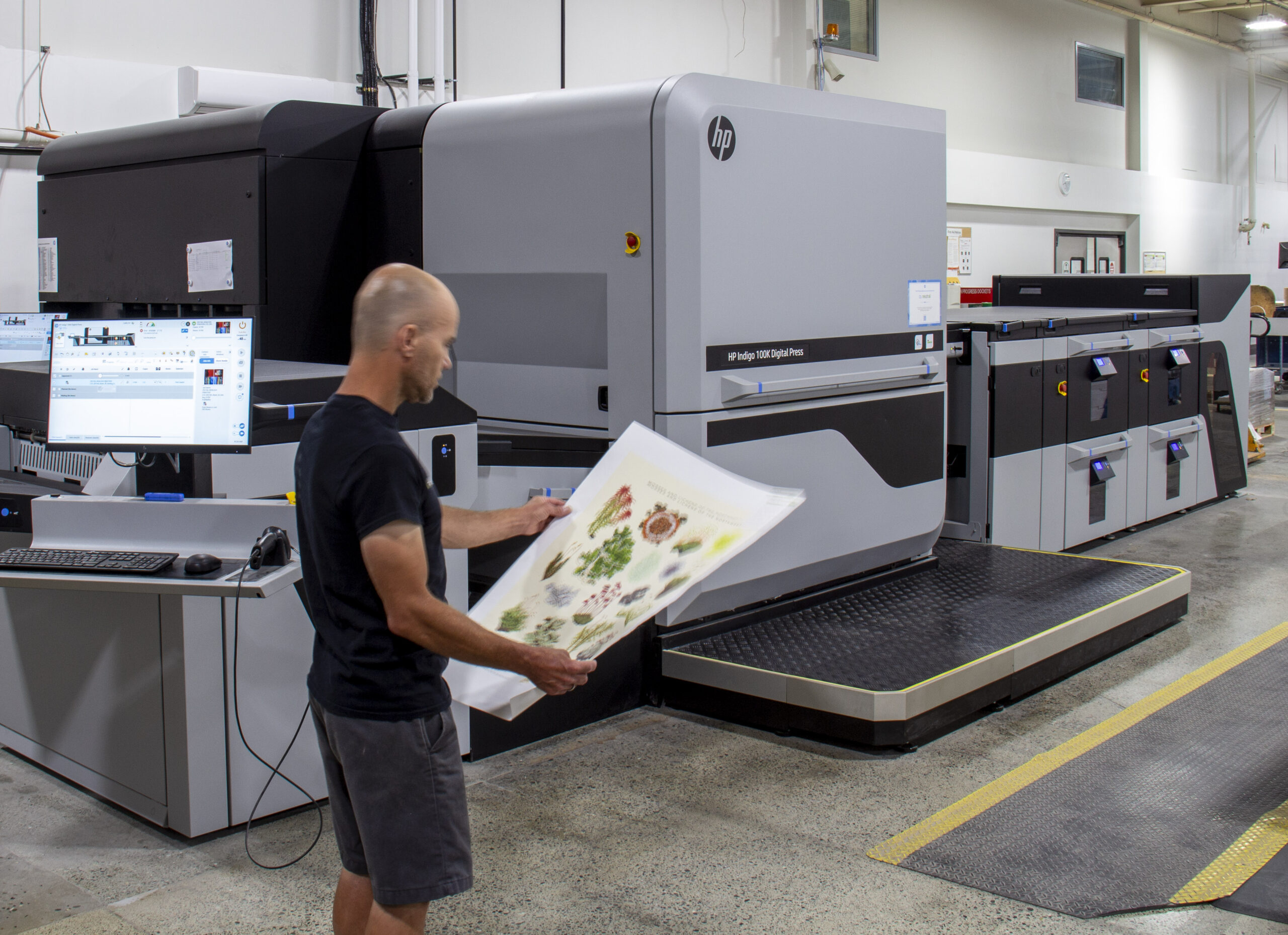

It was produced on Mohawk FSC-certified, 100% post-consumer waste (PCW) materials, Ancient Forest Friendly designation by Canopy, stocks with a cover wrap made from 100% recycled toilet paper and fully printed on an HP Indigo 100K digital press.

Providing the Most Sustainable Direct Mail

Hudson Printing, located in Salt Lake City, Utah, has officially launched SustainableMail.com, a resource designed to empower businesses to leverage the power of direct mail while aligning with their environmental values. SustainableMail.com, which the company believes is the most sustainable solution available for sending direct mail, serves as a platform to help organizations navigate sustainable direct mail solutions, offering practical tools and insights to reduce environmental impact without compromising effectiveness. This initiative underscores Hudson Printing’s ongoing commitment to paving the way for a more sustainable future in the printing industry.“At Hudson Printing, we pride ourselves on being a trusted partner, consistently delivering products that align with our customers’ values,” Nicole Larson, project manager at Hudson Printing, says. “Our commitment to sustainability goes beyond materials like paper, it encompasses every aspect of our processes and business decisions.”

Larson explains that the intent with SustainableMail is that it isn’t just a “transaction, it’s the beginning of a meaningful partnership.”

“As part of our commitment to sustainability, we provide detailed statistics for our customer’s projects, such as the amount of paper waste saved when choosing our eco-choice printing options,” Larson explains. “In addition, we offer other materials like certificates and logos to help our customers showcase their sustainability efforts. It’s not just about choosing to print with us, it’s about building a true partnership.”

Hudson Printing has established four pillars of SustainableMail. The first is, of course, that it is sustainable; the products are just as beautiful as if printed by any other method; and the process is both fast; and affordable. By achieving all of this, it provides customers with a unique service. Not only does it offer optimized mailing sizes; 100% recycled and carbon balanced paper; FSC-certified paper that is both acid- and chlorine-free; biodegradable coatings; and water-based inks that are recycling stream friendly, it is a fully carbon balanced process in both its paper and manufacturing.